Besides, they absorb liquids and swell, leach undesirable products and also get affected by sterilization process. But they tend to be too flexible and too weak to meet the mechanical demands as orthopedic implants. Polymers such as ultra-high molecular weight polyethylene (UHMWPE), polytetrafluoroethylene (PTFE), polymethyl methacrylate (PMMA), polylactide (PLA), polyglycolide (PGA) and polyhydroxybutyrate (PHB) were widely used in various biomedical applications.

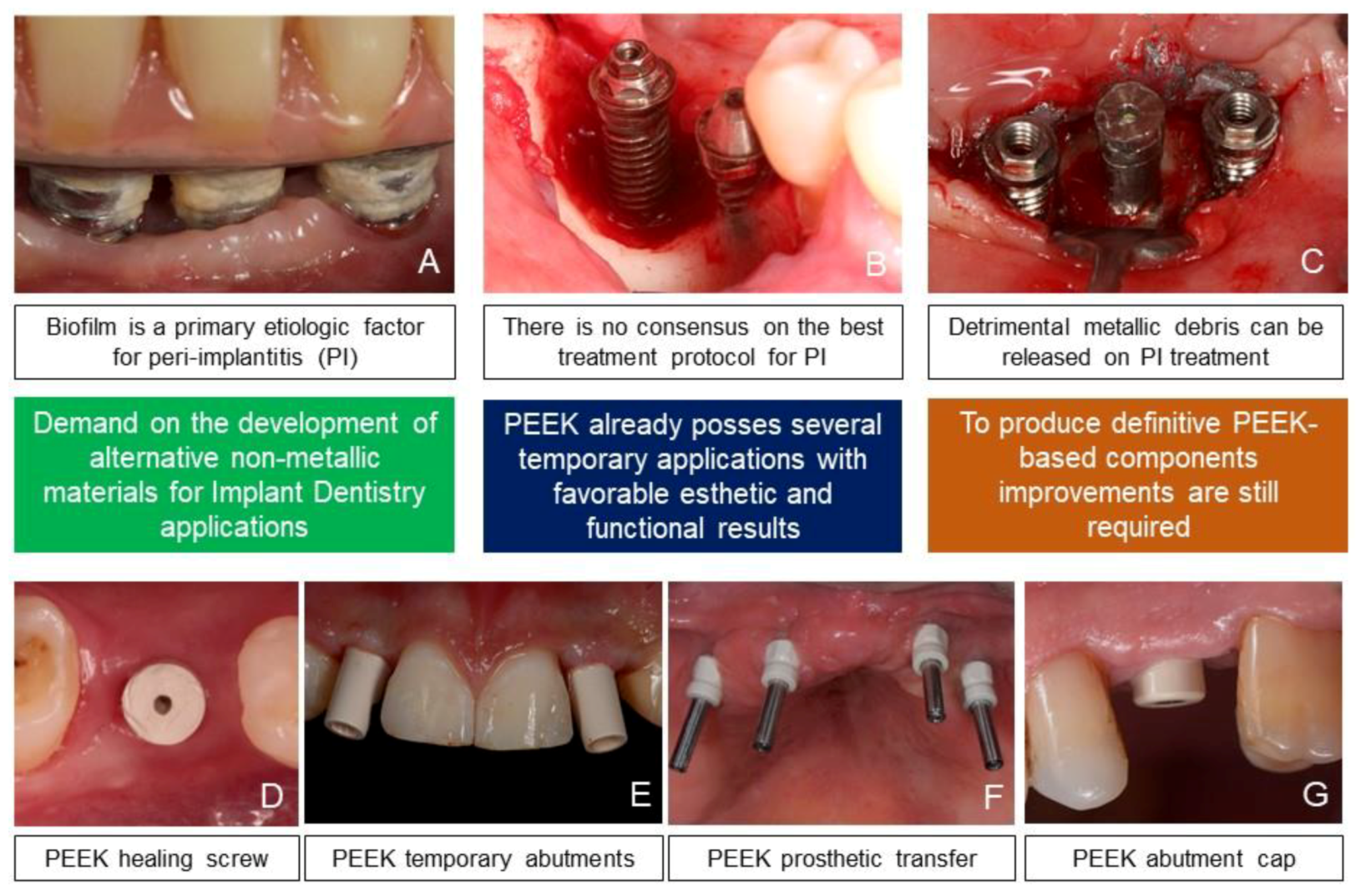

Unfortunately, low- temperature degradation and high Young`s modulus (210 GPa) are potential disadvantages of this material. 10, 11ĭuring the last two decades, efforts are being made to develop metal-free implants, abutments, and restorative materials. Also, the metallic implants cause scattering rays in the field of radiation and its radio-opacity causes artifacts in computed tomography (CT) images and limit the ability to examine the patient with magnetic resonance imaging (MRI). 9 Moreover, the titanium and its alloys have an elastic modulus (102-110GPa) which is significantly higher than bone (14GPa) and resulting in severe stress-shielding on the peri-implant bones, which will lead to adsorption of adjacent bone tissues and cause prosthetic loosening and failure. Due to this event, Ti releases ions and triggers an immune reaction (Type IV) that is potentially directed towards the implant and thereby osteolysis. However, the conditions, such as cyclic loading, implant micromotion, acidic environments, and their combined effects, can result in the permanent breakdown of these oxide film which may lead to exposure of the bulk metal to an electrolyte and thereby corrosion happens pathophysiologically. 8 The corrosion resistance of Ti and its alloys is a result of the formation of oxide films (TiO 2) when comes in contact with oxygen. Titanium (Ti) and its alloys are broadly used as dental and orthopedic implant materials because of high corrosion resistance, biocompatibility, re-passivation, and adequate mechanical properties. 2 Over the past few years, PEEK and its composites have attracted a great deal of interest in the field of dentistry because of its various beneficial properties. 7 In 2012, JUVORA TM was launched to serve the denture market. 6 With the development of carbon fiber reinforced PEEK (CF/PEEK), this new composite material was mainly used for fracture fixation and femoral prosthesis in artificial hip joints. 5 PEEK was commonly used as a material of interbody fusion cage in the vertebral surgery.

1, 2, 3, 4 By the late 1990s, PEEK gained popularity in orthopedic and traumatic applications and started replacing metal implant components. In 1981, PEEK along with its composite material like glass and carbon filled products were commercialized for industrial applications such as aircraft and turbine blades. Historically, it was first developed by UK based Imperial Chemical Industries (ICI) in association with Victrex PLC in 1978.

0 kommentar(er)

0 kommentar(er)